Gas Detection at Battery Charging Stations for Forklifts and Pallet Trucks

Industrial transport vehicles, such as forklifts, are usually electrically powered. They are equipped with lead-acid or Li-ion batteries. During charging, hydrogen is released. In the case of Li-ion batteries, this is due to the electrolysis process of water when residual moisture is removed from the electrolyte, but it can also result from the decomposition of the electrolyte itself. With lead-acid batteries, H2 is produced during charging through the electrolysis of water in the electrolyte solution (35% H2SO4, 65% H2O). Overcharging leads to excessive gas formation due to overheating of the lead-acid battery.

Industrial transport vehicles, such as forklifts, are usually electrically powered. They are equipped with lead-acid or Li-ion batteries. During charging, hydrogen is released. In the case of Li-ion batteries, this is due to the electrolysis process of water when residual moisture is removed from the electrolyte, but it can also result from the decomposition of the electrolyte itself. With lead-acid batteries, H2 is produced during charging through the electrolysis of water in the electrolyte solution (35% H2SO4, 65% H2O). Overcharging leads to excessive gas formation due to overheating of the lead-acid battery.

Hydrogen Risks at Charging Stations for Industrial Transport

At charging stations for electric industrial transport vehicles, there may be a risk of explosion due to hydrogen released during the charging process. It is important to properly design these areas and ensure adequate ventilation. Hydrogen is lighter than air and may accumulate near the ceiling, potentially forming an explosive mixture.

Monitoring Hydrogen Concentration with a Fixed Gas Detection System

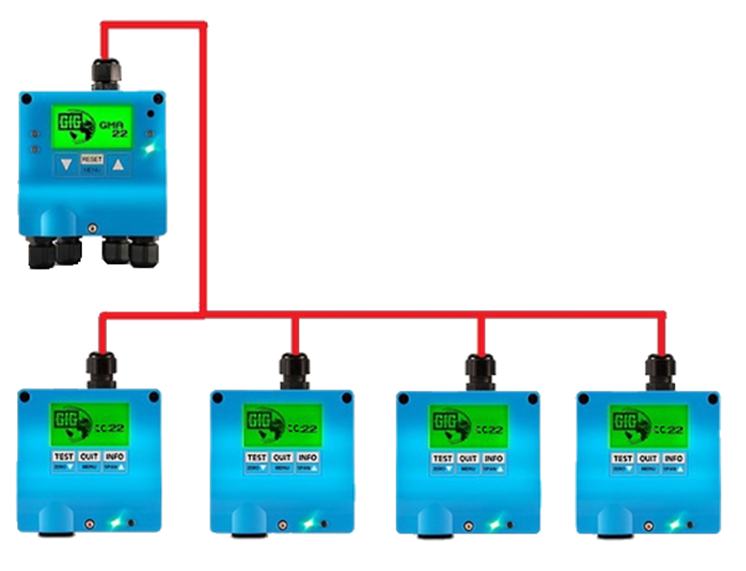

Hydrogen concentration in the room can be effectively monitored using a fixed gas detection system. This provides added safety and security. Ravebo B.V. supplies and installs detection systems consisting of a controller and one or more transmitters equipped with a sensor cell for detecting hydrogen. When monitoring for explosion risk, a catalytic combustion sensor is used, calibrated for hydrogen detection. The readout is shown as a percentage of the LEL (Lower Explosion Level) of hydrogen. If this concentration exceeds a set threshold, an alarm is triggered. This alarm can be linked via a relay to external actions such as activating an external alarm, shutting off the charging station, and/or activating extra ventilation.

Hydrogen concentration in the room can be effectively monitored using a fixed gas detection system. This provides added safety and security. Ravebo B.V. supplies and installs detection systems consisting of a controller and one or more transmitters equipped with a sensor cell for detecting hydrogen. When monitoring for explosion risk, a catalytic combustion sensor is used, calibrated for hydrogen detection. The readout is shown as a percentage of the LEL (Lower Explosion Level) of hydrogen. If this concentration exceeds a set threshold, an alarm is triggered. This alarm can be linked via a relay to external actions such as activating an external alarm, shutting off the charging station, and/or activating extra ventilation.

Features of CC22D H2 Transmitter:

- Measurement principle: Catalytic combustion;

- Range: 0 – 100% LEL;

- Display: 2.2” graphical display;

- Operation: via 3 function buttons;

- Housing: IP54;

- Dimensions: 96 x 140 x 49 mm (incl. sensor);

- Weight: 220 g;

- Power supply: 24 VDC (12 – 30 VDC);

- Output: Analog (0–20 mA or 4–20 mA) or Digital RS-485 (Modbus Protocol);

- SIL: SIL 2/3 (hardware);

- Expected sensor lifetime: 5 years.

Features of GMA22 Controller:

Ideal for smaller gas detection systems (up to 4 transmitters with RS485 output)

- Dimensions: 97 x 140 x 50 mm;

- Housing: IP64;

- Display: 2.2” graphical display;

- Status/Alarm: via 4 LEDs, backlit display, and acoustic alarm;

- Operation: via 3 function buttons;

- Power supply: 24 VDC or 230 VAC (to be specified in advance);

- Integrated relays: 4 (expandable with an external relay module);

- Data logging (optional feature): microSD card.