FTIR Analysis

Innovative Technology for Molecular Gas Analysis

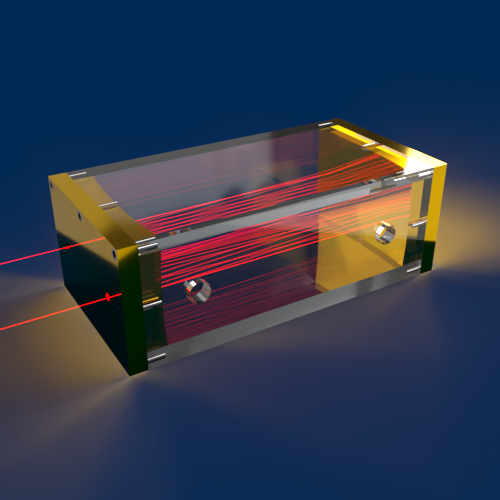

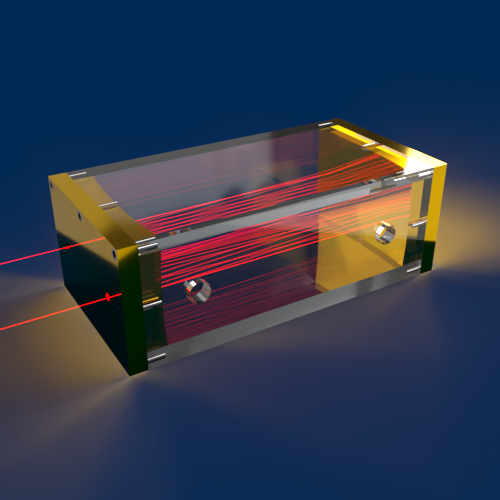

In a time when industrial processes are becoming increasingly advanced and environmental regulations are stricter than ever, the Fourier Transform Infrared (FTIR) analyzer offers a solution for simultaneously measuring and monitoring various gas concentrations. This technology uses infrared spectroscopy to identify and quantify chemical compounds at the molecular level. FTIR analysis provides precision and versatility, making it suitable for a wide range of applications across different industries.

Exceptional Technology

What makes FTIR analysis unique?

The FTIR analyzer stands out due to its ability to measure multiple components simultaneously without compromising accuracy. Unlike traditional methods that often analyze single substances, the FTIR analyzer can detect hundreds of different chemical compounds in a single measurement. This makes the device not only more efficient but also cost-effective, as it requires less equipment and analysis time.

Using the FTIR analyzer

Applications of the FTIR Analyzer

FTIR analysis is used across various industries to measure a wide range of gas components and chemicals. Here are some of the most common applications:

- Industrial Emission Control

- Industrial processes, such as combustion systems and petrochemical production, often generate harmful emissions. FTIR analyzers are used to accurately monitor and control these emissions. We supply FTIR analyzers as complete systems for Continuous Emission Monitoring (CEMS). Our CEMS solutions are QAL1 certified, helping companies comply with environmental regulations and reduce their environmental impact. Even for periodic measurements, we can offer a QAL1-certified FTIR system.

- Chemical Process Control

- In chemical plants, FTIR analysis plays a vital role in optimizing production processes through continuous monitoring of various gas components. The analyzer quickly detects changes in gas composition, providing operators with immediate insight into process effects. Efficiency evaluations and follow-up of parameter adjustments can be performed precisely. This not only increases efficiency but also minimizes the risk of defects or production downtime.

- Research and Development

- FTIR analysis is a powerful tool for research and development, offering detailed insights into molecular structures and interactions. Researchers in various sectors use the FTIR analyzer to monitor specific gas concentrations, as well as for identification and qualitative analysis of processes. FTIR analyzers are used for:

- Research and optimization of carbon capture and storage (CCS) processes;

- Research and optimization of water purification systems, focused on minimizing emissions of greenhouse gases and nitrogen oxides;

- Investigation and testing of incidents and emergencies involving the storage and use of lithium-ion batteries; determining which hazardous gases are released, and at what concentrations, during thermal reactions including combustion;

- Efficiency measurements of gas purification processes. By measuring gas concentrations before and after treatment, the effectiveness of different techniques or additives can be evaluated;

- Research on greenhouse gas emissions from soil air. Gases, including greenhouse gases, are emitted from soil and humid ecosystems.

- FTIR analysis is a powerful tool for research and development, offering detailed insights into molecular structures and interactions. Researchers in various sectors use the FTIR analyzer to monitor specific gas concentrations, as well as for identification and qualitative analysis of processes. FTIR analyzers are used for:

Detection

Common Gas Components Detectable by an FTIR Analyzer

One of the greatest advantages of the FTIR analyzer is its ability to measure a wide range of gas components. Below are some commonly detected components:

- Carbon dioxide (CO₂): A common greenhouse gas found in emissions.

- Carbon monoxide (CO): A toxic gas often released during incomplete combustion.

- Methane (CH₄): A powerful greenhouse gas frequently measured in livestock and agricultural studies.

- Nitrogen oxides (NOx): Common emission gases from traffic and industrial combustion processes.

- Sulfur oxides (SOx): Contribute to air pollution and are typically monitored in industrial emissions where sulfur-containing fuels or materials are used.

- Hydrogen chloride (HCl): Found in the chemical industry, for example, released during galvanizing or electrolysis processes.

- Hydrogen fluoride (HF): Released during waste incineration or the firing process in the ceramics industry.

- Ammonia (NH₃): A well-known emission gas from agriculture and livestock farming.

- Nitrous oxide (N₂O): Known as a very potent greenhouse gas.

- Volatile Organic Compounds (VOCs): This group of compounds plays a major role in air pollution and is a challenge in the oil and gas industry.

Get in touch with us

Why Choose Ravebo as Your FTIR Specialist?

At Ravebo, we have many years of experience in providing high-quality analysis technologies, including FTIR analyzers. Our expertise in consulting, installation, and maintenance of this advanced equipment ensures that you get the most out of your investment. We understand that every company faces unique challenges and that a standard solution is not always sufficient. That’s why we offer customized solutions tailored to your specific needs and requirements.

Our team of specialized consultants guides you through the entire process — from selecting the right analyzer to implementation and training. We are known for our customer-focused approach and work closely with our partners to ensure you have access to the latest technologies and the best possible service. Ravebo is your reliable partner in FTIR analysis, and we are committed to supporting you in achieving your environmental goals and operational efficiency.

Get in touch with one of our specialists

Ravebo stands for sustainable cooperation with its clients. Both within Ravebo and with our manufacturers, we work with short and direct lines — and that’s practical! We are happy to get started with your request for your application in measuring and monitoring dust and gases.