Measurement Techniques for Nanoparticles in Air

The mass of nanoparticles is usually so small that it cannot be measured. However, the particle number concentration can be very high. Measurement techniques for determining nanoparticles in air therefore result in the number of particles per cm³.

CPC (Condensating Particle Counter)

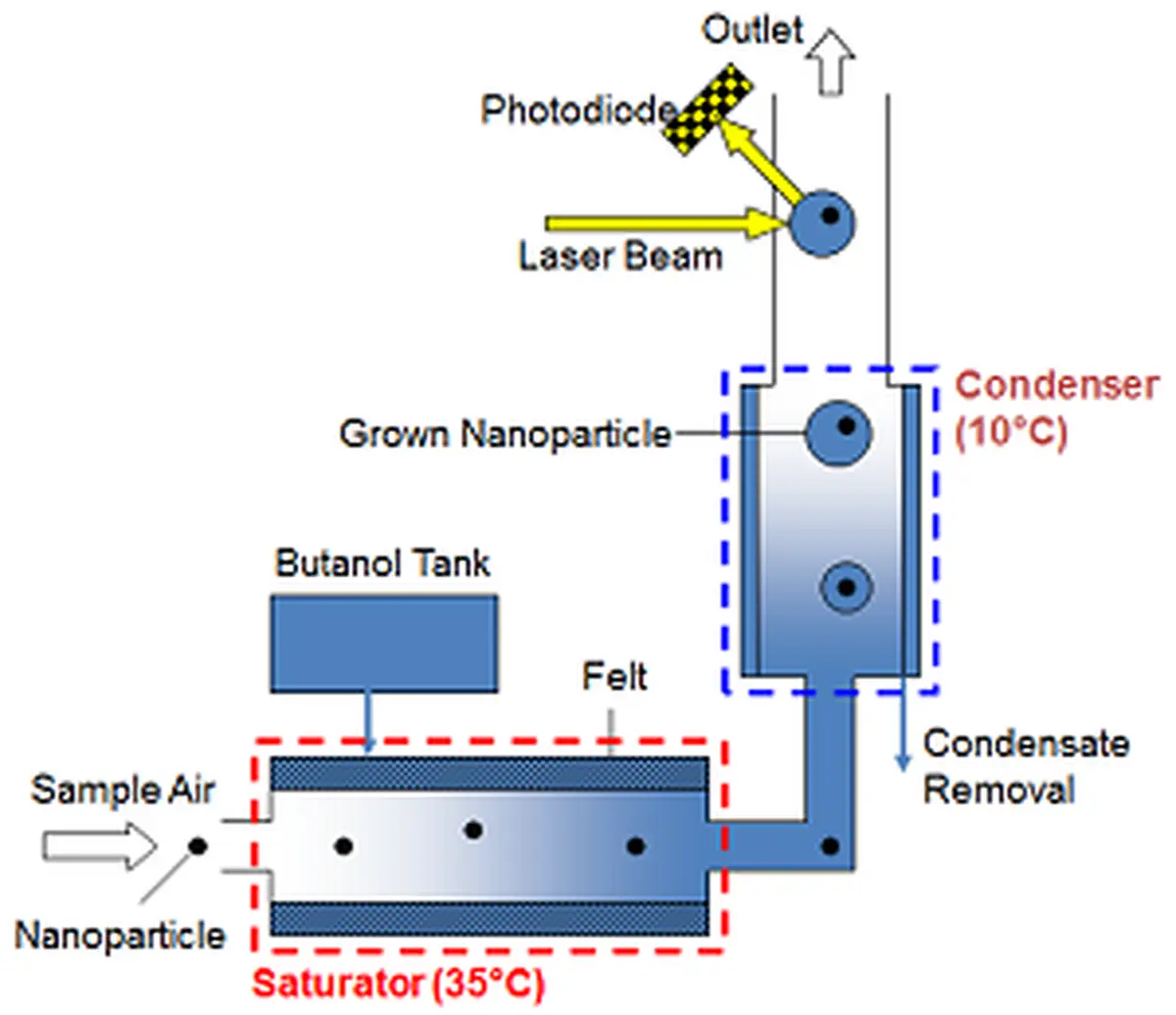

Optical measurement techniques cannot directly detect nanoparticles because they are too small to produce a signal. The particles are “invisible” to optical techniques such as LSAS (Light Scattering Aerosol Spectrometry). If the particles were enlarged, they could be detected by an optical particle counter. This is exactly what happens in a Condensating Particle Counter (CPC). The air sample passes through a saturation chamber, and condensation is achieved by lowering the temperature. The particles act as nuclei onto which condensation occurs. The result is larger particles that can be counted using a laser. Butanol is commonly used because it condenses on 99% of particle types. Butanol is suitable for both hydrophilic and hydrophobic particles. This is important in ambient air measurements due to the variety of particle types.

Optical measurement techniques cannot directly detect nanoparticles because they are too small to produce a signal. The particles are “invisible” to optical techniques such as LSAS (Light Scattering Aerosol Spectrometry). If the particles were enlarged, they could be detected by an optical particle counter. This is exactly what happens in a Condensating Particle Counter (CPC). The air sample passes through a saturation chamber, and condensation is achieved by lowering the temperature. The particles act as nuclei onto which condensation occurs. The result is larger particles that can be counted using a laser. Butanol is commonly used because it condenses on 99% of particle types. Butanol is suitable for both hydrophilic and hydrophobic particles. This is important in ambient air measurements due to the variety of particle types.

Determining the Number of Particles

A CPC is a good instrument for determining the total number of nanoparticles. When used for ambient air measurements, proper conditioning is important to prevent water condensation in the system. Two key specifications of a CPC are the “single-count” range and the “count efficiency.”

Single Count Range

The single count range indicates the maximum concentration that can be measured without coincidence error. The total range may be higher because the manufacturer corrects for this effect, but the uncertainty can increase (up to 50%!). It is better to apply dilution or use another technique.

Count Efficiency

Count efficiency indicates the smallest detectable particles. This is shown as the D50 value, the particle size at which 50% is detected. This value also depends on the particle type, which is not always defined in the instrument documentation. Many compact portable monitors have a D50 value over 15 nm, whereas a good scientific CPC can detect down to 3–5 nm. These will yield significantly higher results in most cases. CPC results should not be directly compared based solely on total counts — specifications and application must be considered when drawing conclusions from comparative research.

DMA (Differential Mobility Analyzer)

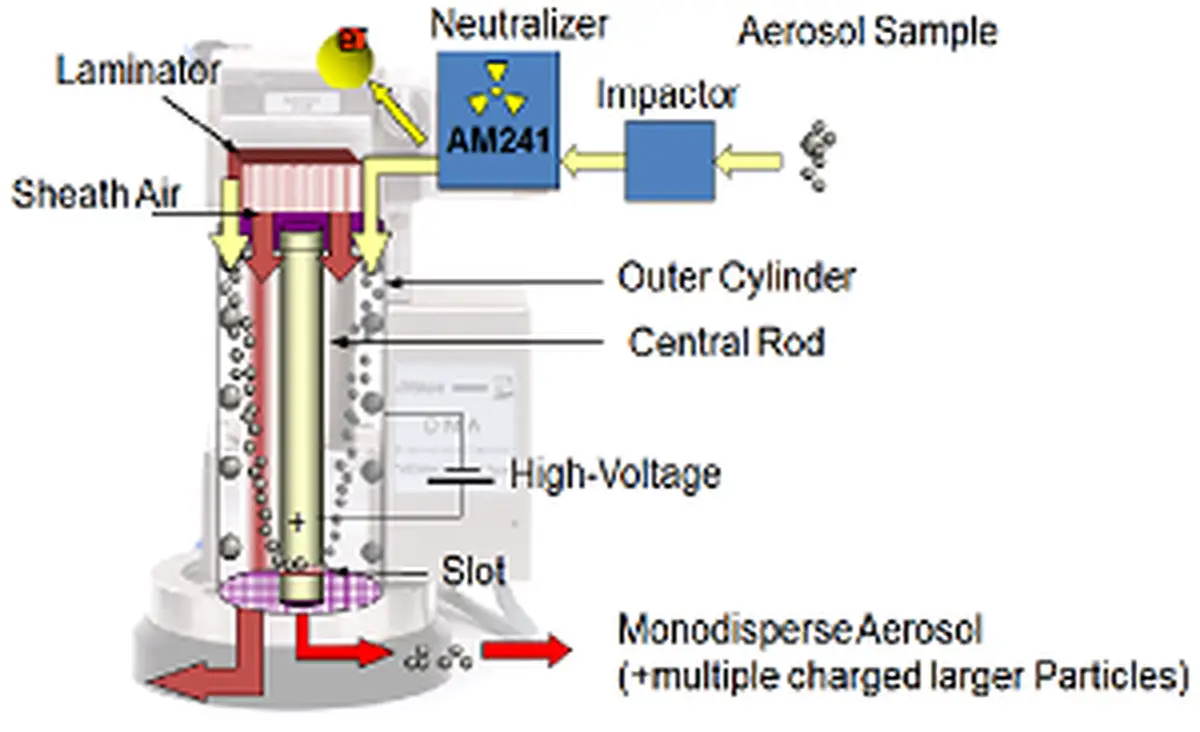

A particle size distribution is obtained by first separating particles by size and then counting them. A DMA (Differential Mobility Analyzer) is used to separate particles based on electrical mobility. A neutralizer creates a standard charge distribution. Then, particles are separated using a voltage difference in the DMA. By stepping through the voltage, a complete scan of the size distribution is made. Software calculates the concentration based on the total entering the DMA. The full system is typically referred to as an SMPS (Scanning Mobility Particle Sizer). A radioactive neutralizer is common, but non-radioactive alternatives are available. The particles exiting the DMA carry one or more charges.

A particle size distribution is obtained by first separating particles by size and then counting them. A DMA (Differential Mobility Analyzer) is used to separate particles based on electrical mobility. A neutralizer creates a standard charge distribution. Then, particles are separated using a voltage difference in the DMA. By stepping through the voltage, a complete scan of the size distribution is made. Software calculates the concentration based on the total entering the DMA. The full system is typically referred to as an SMPS (Scanning Mobility Particle Sizer). A radioactive neutralizer is common, but non-radioactive alternatives are available. The particles exiting the DMA carry one or more charges.

FCE (Faraday Cup Electrometer)

Using a Faraday Cup Electrometer (FCE), current in fA can be measured and then converted via software to the total number of particles that entered the DMA. The FCE has a fast response but cannot detect absolute zero. A minimum concentration (number of charges) is needed to produce a signal above noise level. The FCE is commonly used as a reference instrument for calibrating CPCs.

Nano Sensors

Electronic nano sensors use the electrometer for final measurement. Upstream, particles are charged using ion exposure. Depending on the instrument type, various techniques are used to filter residual ions and use electrical mobility to record values with the electrometer. Through calculation, average particle size and concentration are determined — or estimated. These instruments are calibrated using an SMPS system.