Gas Analysis and Detection Systems

Expanded capabilities for the inspection and calibration of gas analysis and detection systems.

Advanced Techniques for Gas Analysis Systems

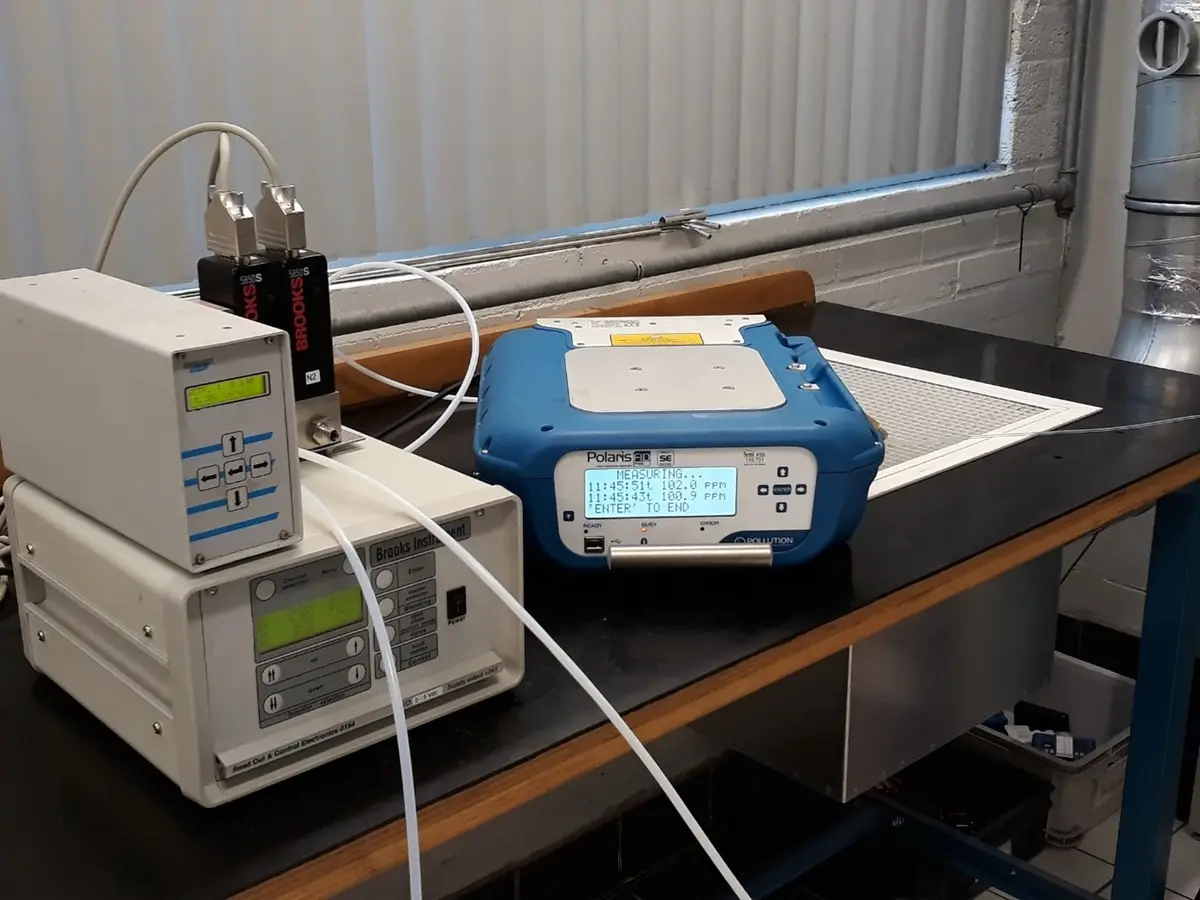

Recently, we have further expanded our capabilities in the calibration and inspection of gas analysis systems. Using certified Mass Flow Controllers (MFCs), a gas mixing manifold, and validated calculations, we can create traceable concentrations using certified gas mixtures.

Recently, we have further expanded our capabilities in the calibration and inspection of gas analysis systems. Using certified Mass Flow Controllers (MFCs), a gas mixing manifold, and validated calculations, we can create traceable concentrations using certified gas mixtures.

This allows dynamic dilution from a concentrated reference gas and a matrix gas (e.g., air).

Formula for Gas Analysis

Key Parameters in Gas Analysis

Where:

| • | Xa | : | Mole fraction of the component in the final mixture |

| • | X1a | : | Mole fraction of the component in the reference gas |

| • | X2a | : | Mole fraction of the component in the matrix gas (impurity) |

| • | Q1a | : | Flow from the Mass Flow Controller of the reference gas |

| • | Q2a | : | Flow from the Mass Flow Controller of the matrix gas |

Certified Mass Flow Controllers

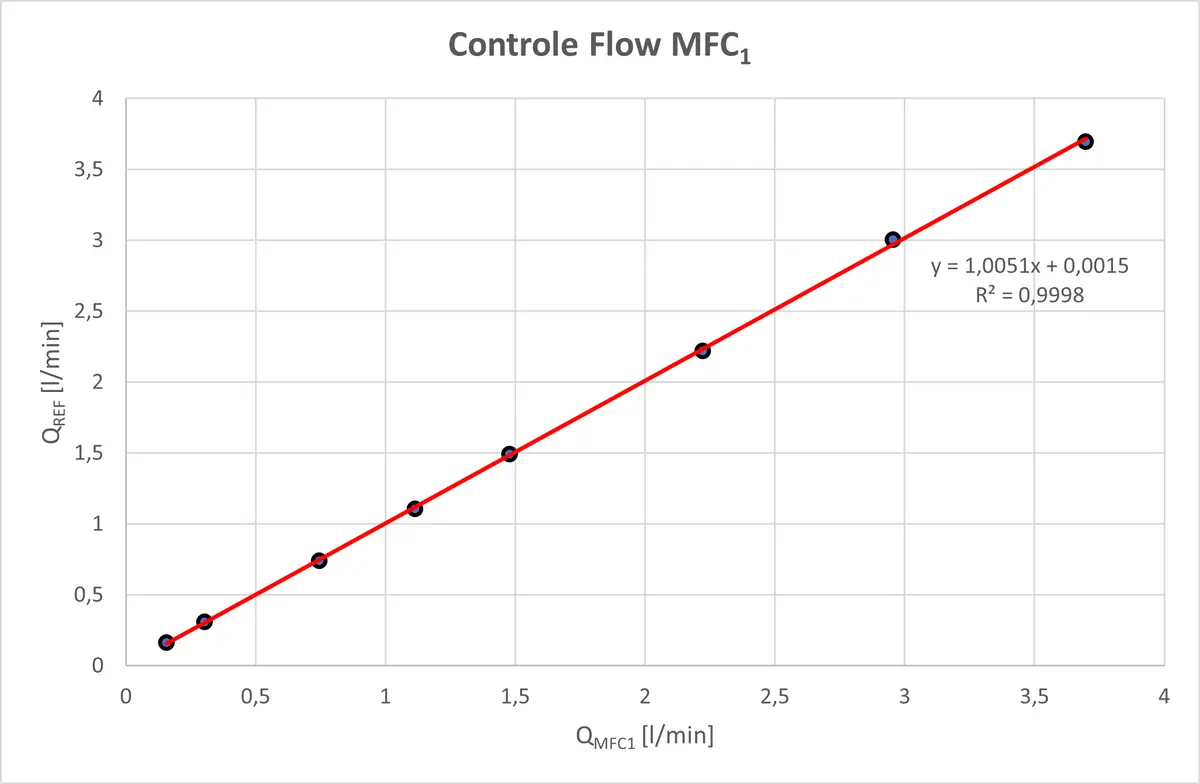

As mentioned, the Mass Flow Controllers are certified. Naturally, we have performed validations on them. All MFCs passed the tests regarding flow validation. Here is an example:

Linearity and Cross-Interference Tests

Linearity Test

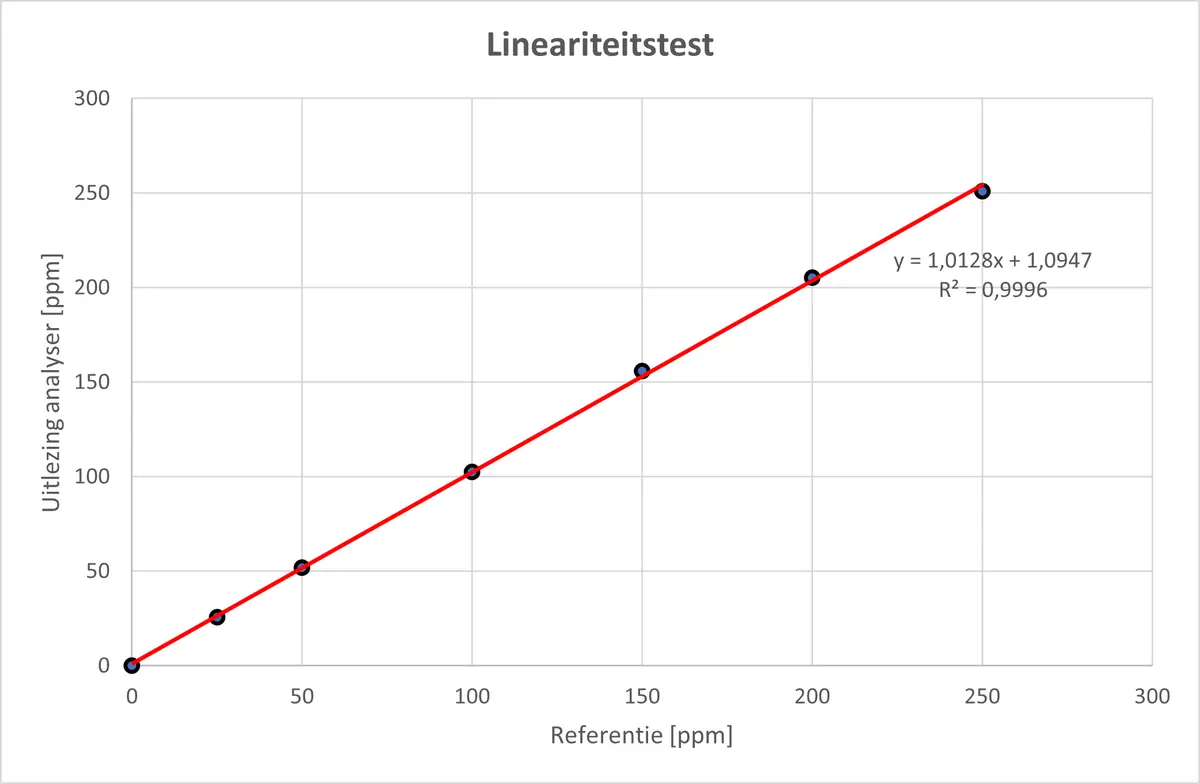

With this system, Ravebo B.V. can perform linearity tests on your analyzer or detector. Normally, gas analyzers are electronically linearized, so calibration is typically done using a zero gas and a span gas. We can now demonstrate whether the system’s response is truly linear, by offering multiple gas concentrations evenly across the measuring range:

Cross-Interference Test

We can currently mix from 3 gas cylinders. This allows not only linearity testing but also cross-interference testing. For example, it’s known that the oxygen concentration affects FID monitor readings. We perform an “oxygen synergy” test to determine how different O₂ levels impact the measurement signal.